At that time, there were still many dirt roads outside cities in Japan, apart from toll roads, so I adjusted the suspension to be a little softer, but if the road conditions were the same now, I think I would have adjusted it to be harder.

I believe there were 6 people involved for the test ride in Europe in mid 1970 to early 1971.

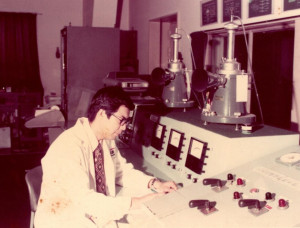

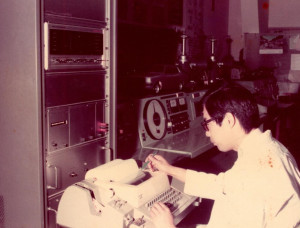

Mr. Takei was a chief, and Mr. Kamata was there too. Mr. Kamata whom to be credited as an A1 qualified test driver.

A1, is the highest rank in Nissan who has outstanding skills for evaluating feelings and handling character of vehicles.

Actually, he is the one who took me as a buddy of the handling evaluation, and he pointed out the imperfections of prototype coil springs in just a few seconds.

Of the six people, two were selected from the Oppama Experimental Department to participate.

In Europe, there are highways with speeds of up to 200 km/h, and the L24 engine is designed for 200 km/h. Therefore, our team also discussed what kind of suspension should be used for the car we would take on the expedition.

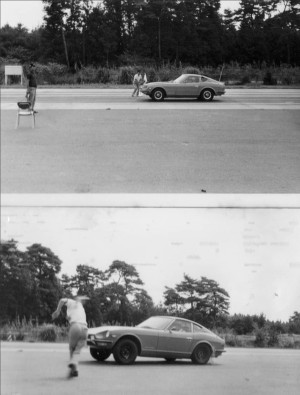

It was decided that the suspension of the S20 engine specification, where driving performance was most important, would be the best. Therefore, the suspension of the vehicle was modified to the North American specification, and before shipment, an initial test drive of the vehicle to the European specification was carried out on the test track in Yatabe, which was quite well received. The test car was sent to the Netherlands.

The expedition team was based at Datsun Nederland, where they evaluated the car's performance. However, the report they received two weeks later was not so positive, with the comment that “the S20 specification suspension was too soft, and it was impossible to reach the top speed”.

I was in Japan to co-operating for the Euro spec development. When I got the request from the team in Europe, my team and I selected alternative parts to be seemed proper and shipped to Europe.

What made me annoyed was, their request was always not seemed well considered.

Soon after the test began, they requested much softer coil springs. I sent three different sets of springs and shock absorbers to them.

3 weeks later, they requested a much stiffer suspension set up because the previous ones were too soft for the road.

Later on I became to realize that they didn’t test on highway but in town with the stiffer set up. Also, they didn’t test in town but on highway with the softer set up.

My colleague also felt uneasy about their requests and said, "Let’s send the one as hard as hell!"

I took his word and decided to send the ones which were applied to the Works Monte Carlo cars.

You know what they replied? It was too stiff!

But finally the team reached what they think good. And Datsun Netherlands said "Excellent" in early 1971.

It was a story of old days, everything was like that in communication, not like internet world today.

About the European specifications

The S30Z was announced in October 1969 and a 50,000 km endurance test was started on the Tomei Expressway between Yokohama and Hamamatsu, using two cars, the L24 from North America and the L20.

The S30Z was designed for two passengers, so one person would be the sole driver, while the other person could be a passenger of the development department's choice.

At that time, the Tomei highway had no sound barriers, and when driving out of tunnels or crossing hills, there were about 40 instances of crosswinds on the way to and from Hamamatsu.

However, with a maximum speed of 100 km/h, there was no cause for concern, and the highway was considered to be one of the most stable in the country.

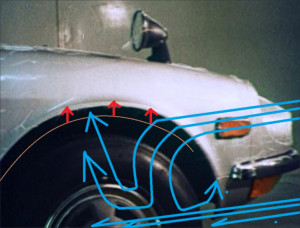

In the Tomei Endurance Test, it was fine to accelerate to 120 km/h when overtaking due to the legal speed limit of 100 km/h. However, when the speed inevitably exceeded 140 km/h depending on driving conditions, some people felt uncomfortable because when there was a crosswind, the front of the car would be pushed toward the wind direction.

However, since this was above the maximum speed allowed in Japan, it did not improve the evaluation.

The high-speed, long-distance vehicle can reach speeds of up to 150 km/h on the Oppama test course before entering the curve, but since the course was surrounded by walls, there seemed to be no problem in the left-hand direction.

Even in our team, when we finalized the confirmation of the car's performance before it went on sale at the end of September, we conducted a right-hand drive test on the Oppama test course, which is not normally possible, and we confirmed that the car started to sway in a strong crosswind at a speed of about 125 km/h. We had already come up with several countermeasures, such as front and rear spoilers and a blunt nose, but we were still considering reinforcing the suspension as a countermeasure without changing the car's appearance.

Even in Japan and North America, where the car is sold, the maximum practical speed is around 120 km/h, so no problems were reported.

To improve high-speed stability without changing the appearance, the only options are to change the stance of the car or stiffen the suspension.

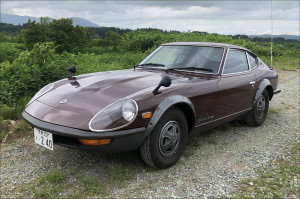

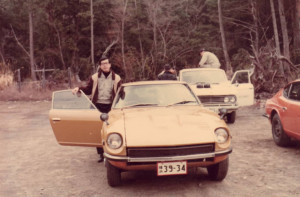

So I decided to lower the front by 15mm and change the stance to horizontal when I stop for photos and to 100km/h when I drive.

*Furthermore, I asked a research center (Y51) that specializes in tuning car racing to make me softer S30Z rally springs and shock absorbers, and sent them by air freight to a Datsun dealer in the Netherlands.

Mr. Kamata instructed the local staff to assemble the parts, but the evaluation was as expected: “OK” for high-speed stability, but the shocks on cobblestones were too strong, so it was a no-go.

Taking this evaluation into account, we sent three copies each of the following parts: loose shock absorbers, springs and stabilizers, and asked Mr. Kamata to assemble them according to his opinion of a good specification.

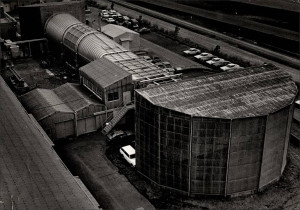

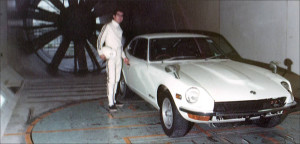

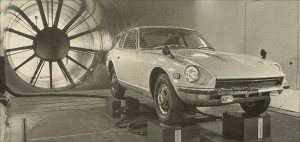

It seems that it was difficult to adapt them to all road conditions, but we also assembled the same suspension that Mr. Kamata had assembled in the Netherlands, and we worked together to solve the problems by assembling a crosswind generator on the Oppama test course.

Since we were focusing on the high-speed stability of the NG items, we tested the specs recommended by Mr. Kamata on the Oppama test course, and they were well received there as well. The specs we planned to request from the local tuning factory were evaluated as better than the final specs, and we were able to get an excellent evaluation from the local dealer (Datsun Nederland) in the end.

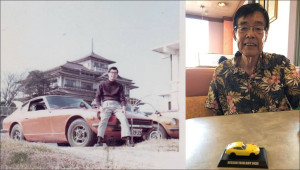

When the European version of the S30Z was developed, there was not only an exchange of ideas between different models, which had not happened before, but also collaboration with the research center (Y51), which had not been involved in the development of production vehicles up to that point. I think it's fair to say that the car was created by the Nissan Motor Company as a whole.

More than 50 years have passed since then, but no other car has been developed by the entire company, and I think the S30Z is the greatest treasure Nissan Motor has created.

I was involved in the development of the S30Z, and it was a constant struggle, but I also experienced the satisfaction of solving the problems, and I think that in my life I can be proud of being able to send the S30Z out into the world.

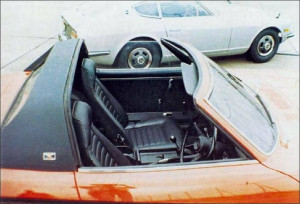

The final Euro-spec front spoiler

We were trying to reduce the drag with adding a front spoiler. It was not really oriented to development of Euro versions.

We tried various height from the ground. A bigger spoiler gets much better results in reducing the front lift but worse in drag.

Today, you see the Euro front spoiler was originally a bit wider in vertical, which means a bit closer to the ground (approximately 10mm.)

But what made the Euro front spoiler as it has the size today?

It because of the tire stopper height at the parking lot in Japan. Late 1960s Japanese roads still yet to be unsophisticated, especially in countryside. Several highways had begun to operate, but not so popular for many people.

Then the tire stoppers were not always the same height, they varied a lot.

So we took advantage of avoiding scratches. Maybe we checked how the tire stopper in Europe, but I can’t remember that.

I don’t know why the fron spoiler, it wasn’t available in Japanese market.

Creating a new car

Many people think that a car is created by a designer coming up with the shape, creating the design for each part, making a prototype with each part, and when it is assembled, checking the performance in a test, and then it is finished.